Software

Solutions

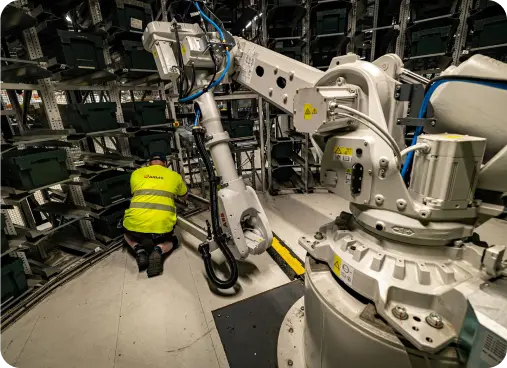

Arms Innovations provides cutting-edge software solutions designed to streamline the service and maintenance operations of assets for world-leading brands. Our software caters to a wide range of sectors, including retail stores, conference centres, gyms, hotels, manufacturing and logistics sites.

We offer mobile applications and contractor management portals, enabling efficient management of maintenance resources. Our unique technology integrates seamlessly with automated machinery and building infrastructure to automatically generate and triage work tickets in real-time, significantly reducing repair lead times and administrative tasks by efficiently organising and scheduling maintenance activities.

We offer mobile applications and contractor management portals, enabling efficient management of maintenance resources. Our unique technology integrates seamlessly with automated machinery and building infrastructure to automatically generate and triage work tickets in real-time, significantly reducing repair lead times and administrative tasks by efficiently organising and scheduling maintenance activities.

ARMS On-Site

Software Solution

ARMS On-Site Software Solution provides an all-in-one platform for efficient asset management and maintenance operations. With features for fault detection, inventory control, H&S Management and maintenance scheduling, it helps businesses reduce costs, ensure safety, and improve the productivity of maintenance teams across their facilities.

Features: Arms On-Site

Software Features

Asset Database Management

Track asset information: warranty, value, depreciated value, replacement price, maintenance cost, and history.

Parts and Inventory

Management

Spare parts tracking and stock quantity management, automatic order replenishment and analytics for recommended max and reorder levels.

Purchasing

Module Issue purchase orders for maintenance and capital purchases to suppliers and contractors, report against spends by account codes and cost centres, visualise planned versus reactive maintenance spends.

Work Record Management

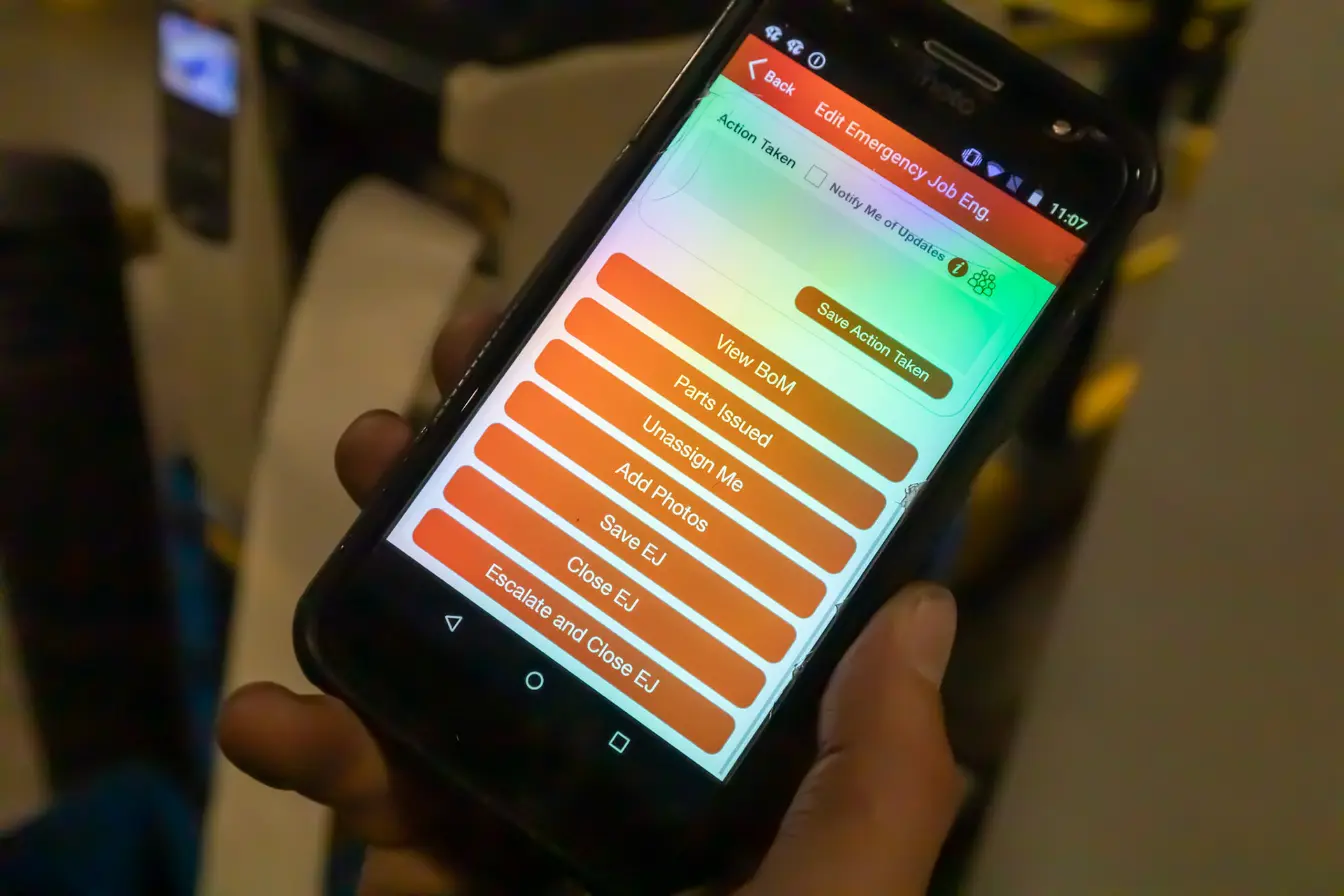

Assign reactive works to employees and contractors, raise maintenance issues for repair via easy to use web portal with interactive site maps.

Planned Maintenance

Scheduler

Assign reactive works to employees and contractors, raise maintenance issues for repair via easy to use web portal with interactive site maps.

Health and Safety

Management

Risk assessment database and COSHH (Control of Substances Hazardous to Health) database, allows for linking risk assessments and COSHH guidance to tasks for visibility of safety controls and guidance. Engineers can conduct risk assessments at the point of work on mobile devices to ensure safety measures are in place.

Reporting and Dashboards

Report on priority problems and site issues, uptime and availability, planned maintenance, work record back log, workforce productivity and more.

Mobile Apps

For Engineers, Operations and Cleaning Personnel to access asset documentation, schematics, manuals, and historical maintenance data. Provide quick, safe, and effective repair solutions for machine faults. Time logging and productivity tracking ensures personnels time against jobs is measured to track work demand and productivity.

Accident & Incident Reporting

Allows employees across the business to report accidents, incidents and near misses through web portals and mobile devices, with template questionnaires, investigation forms and counter measure tracker and management.

Planned Maintenance

Scheduler

Assign reactive works to employees and contractors, raise maintenance issues for repair via easy to use web portal with interactive site maps.

SCADA, BMS, PLC, and WCS

Integration

Real-Time work record creation through advanced integration tools generates and assign work tickets for faults to employees and contractors automatically.

Lone Worker Monitoring

Continuous safety prompts and escalation for non-responsive lone workers.

Training and Learning

Management System Course library links training to roles and tasks, provides e-learning tools, and prompt personnel for training via e-learning if not qualified to assign onto tasks.

Spot Check Module

Ensure housekeeping standards with photo evidence for visual checks.

Accurate Availability

reporting

Recording accurate downtime through integration enables for reporting on asset availability and performance.

Cleaning Activities

Management Digitised and Scheduled Cleaning Activities. Notify engineers of lockout and tagout requirements for machinery during cleaning and prompt engineers to provide evidence of padlocks on isolation points to ensure compliance and safety.

Machine Fault Data Logging

Plus Insight Log fault data for analysis to identify priority problems and drive continuous improvement.

IoT and Condition-Based

Monitoring Platform

Wireless sensor integration for condition monitoring, automatic fault detection, and ticket generation.

Spot Check Module

Ensure housekeeping standards with photo evidence for visual checks.

Advanced Analytics Tools

Continuously analyse the frequency of faults and errors on machines and building infrastructure. Alert maintenance personnel to investigate developing issues and prevent costly unplanned downtime.